NVIDIA GTC 2025: GPU-acceleration is unlocking new possibilities for real-time simulation and predictive modeling.

AI-powered virtual models are becoming transformative for engineering and manufacturing. Enhancing conventional computational fluid dynamics (CFD) and computer-aided engineering (CAE) with technologies such as NVIDIA’s graphics collaboration platform Omniverse, powered by the latest GPUs, can enable real-time visualization, promising shorter development cycles and greater precision.

These innovations in simulation technology were discussed during a session at NVIDIA GTC 2025, in San Jose California, between Vertiv’s Chief Innovation Officer Gregory Ratcliff and Rongguang Jia, distinguished engineer, and Jeremy McCaslin, product manager, from simulation specialist Ansys.

Vertiv has been collaborating with Ansys to digitally transform its design of data center cooling systems. By leveraging Ansys’ advanced simulation tools, Vertiv gains access to better engineering resources that reduce time to market and enhance the reliability of designs. This partnership will also help Vertiv improve scalability, enable early decision-making, and empower sales teams.

The talk highlighted Ansys’ use of NVIDIA’s Omniverse Blueprint, a framework for metaverse application development, alongside CUDA, a GPU accelerated parallel computing platform, and Modulus neural network toolset for model creation and training. Omniverse enables real-time simulation and visualization, powered by Grace processors for AI/HPC, Hopper GPUs for accelerated computing, and Blackwell technology for advanced computational performance.

GPU-accelerated simulations

A key focus was the optimization of CFD for GPU computing. Ansys’ Jia explained how Ansys has tailored its CFD solver to NVIDIA’s hardware. “We’ve adapted our CFD algorithms to fully utilize GPU computing. This enables us to perform physics simulations with greater speed and accuracy, reducing high-fidelity analysis times significantly.” He cited a specific case: a 2.5-billion-cell automotive simulation, which once required nearly a month on 2,048 CPU cores, now completes in just over six hours using 320 NVIDIA GH200 Grace Hopper Superchips. This improvement demonstrates how GPU acceleration can shorten simulation timelines while maintaining precision, offering engineers a more efficient workflow.

AI-powered design optimization

The integration of NVIDIA’s Modulus AI framework was presented as a tool for enhancing design processes. Ansys’ McCaslin highlighted its practical benefits: “Modulus allows us to quickly explore design options and identify optimal configurations. It’s about improving designer productivity by letting AI manage the complexity of design space exploration.” This approach enables engineering teams to evaluate numerous possibilities rapidly, supporting data-driven decisions without the delays of traditional methods. By combining AI with high-fidelity simulations, Modulus facilitates faster iteration, helping engineers refine designs more effectively.

Connecting simulation to reality

The session also showcased NVIDIA’s Omniverse’s real-time visualization capabilities. Ratcliff emphasized its utility: “With Omniverse, we’re not only simulating but also presenting results in a clear, actionable way.” The platform delivers detailed renderings—covering materials, lighting, and assets—that closely resemble physical prototypes. “The rendering quality connects simulation to real-world outcomes,” Ratcliff noted, referencing examples displayed during the talk. This visualization tool supports better interpretation of simulation data and fosters collaboration by providing a precise, shared view of digital twins across teams. (See Figure 1)

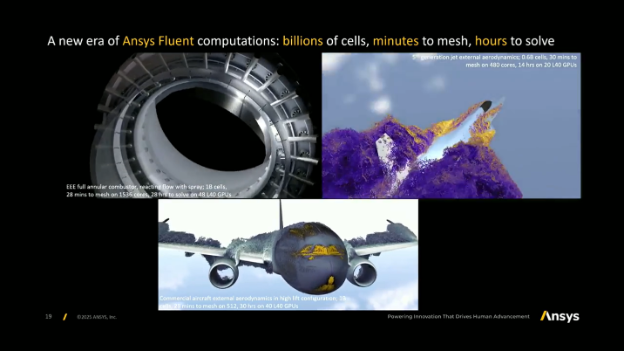

Figure 1: A slide featuring three simulation images: one of a jet engine combustor, another of a fighter jet with aerodynamic flow visualizations, and a third of a commercial airplane in high-lift configuration. Each image contains details about cell counts, meshing times, and GPU usage.

Digital twins in practice

Precise use cases for AI-driven digital twins, drawn from Ansys expertise, were also discussed. Jia emphasized their impact on industrial design: “We’re simulating entire engine systems—thermal flows, stress points—reducing validation from weeks to days.” This efficiency accelerates refinement of heavy machinery and powertrains, bypassing extensive physical testing. McCaslin broadened the scope: “Modulus optimizes heat exchangers or HVAC systems rapidly—any application involving fluids or heat transfer benefits.” Across automotive, aerospace, and energy sectors, these examples highlight digital twins as powerful tools for streamlining complex engineering challenges and enhancing precision.

Advancing multi-scale modelling

The practical value of AI-driven digital twins was also underscored by Vertiv’s Ratcliff: “Omniverse puts everyone—engineers, designers, execs—in the same virtual room, seeing and tweaking the same model live. This isn’t a one-trick pony—it’s built to tackle data centers, factories, even smart cities, anywhere complex systems need a shake-up.” The core message goes beyond speed—it’s about redefining collaboration and equipping teams to solve tough challenges with precision and scale.

To dive deeper into this game-changing technology, watch the full GTC session here:

AI-Driven Digital Twins: Real-Time Physics and Accelerated Simulation Using NVIDIA Technologies