Overview of Coolant Distribution Units (CDUs) in Data Centers

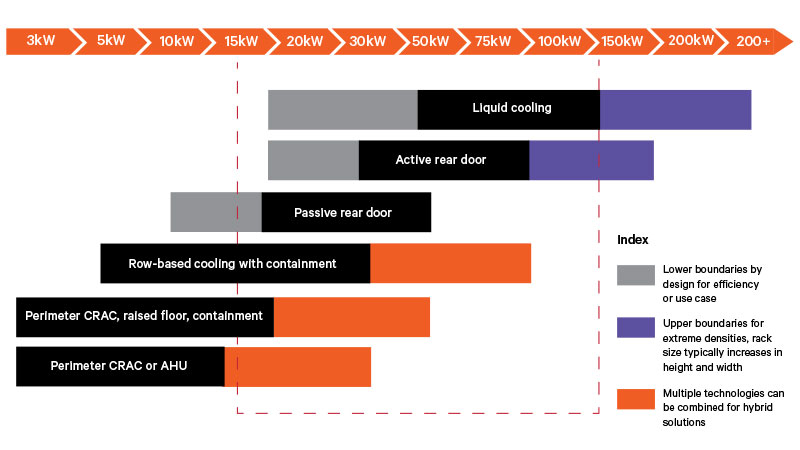

IT cooling challenges continue escalating as new server-accelerated compute technologies, machine learning, artificial intelligence, and high-performance computing drive higher heat densities in the data center environment. Liquid cooling is rapidly emerging as the technology for efficiently handling power-dense hot spots. As the chart below shows, as rack density increases in the data center, air is not as effective as liquid in cooling the load.

How cooling technology evolves as rack density increases in the data center.

Using Liquid to Supplement Existing Facility Cooling Systems

For high-powered CPUs and GPUs to operate within specification, known as maintaining within case temperature, the coolant distribution unit (CDU) offers a broader range of cooling capacity, higher efficiencies, and a more flexible solution than traditional air-cooling options.

A CDU is designed to manage high heat loads for accelerated compute and high-density data center environments, providing critical cooling capacity and heat removal functions. The CDU provides controlled, contaminant-free coolant for heat exchangers, direct-to-chip, and immersion cooling devices.

What is a Coolant Distribution Unit?

CDUs are an integral part of liquid cooling systems designed to increase overall system efficiency and reduce the total cost of ownership for high-density applications in the data center.

The CDU circulates and pumps coolant in a closed-loop system within the rack and server chassis and utilizes facility water (in full liquid cooling systems) and the air outside the rack to cool the servers.

Liquid is More Effective at Transferring Heat

Because liquid is more efficient than air at transferring heat, CDUs can be introduced where higher rack densities have increased the heat being produced beyond the capability of air-cooled systems. The CDU network exchanges heat between the building’s existing facility cooling systems or liquid loop (FWS) and the CDU loop (TCS), which runs closer to the IT equipment.

Vertiv™ XDU, Coolant Distribution Unit with a raised floor

How do CDU Units Work?

Coolant distribution units create an isolated secondary loop separate from the chilled water supply, enabling strict containment management and precise control of the liquid cooling system's temperature, pressure, and flow rate.

The CDU maintains the secondary loop supply temperature above the dew point of the data center, preventing condensation and ensuring 100% sensible cooling.

Whether self-contained in-row CDUs or integrated in-rack CDUs, liquid-to-liquid coolant distribution units must be connected to the existing FWS supported by a heat exchanger that facilitates the transfer of heat out of a CDU.

Vertiv™ XDU, raised floor, front view, close up

Vertiv™ XDU, Rear view

For a liquid-to-air system, the CDU transfers the heat to the ambient supply utilizing a heat exchange coil design within the CDU.

CDUs are equipped with filters, typically 50 microns, to keep the water supply contaminant and debris free and to protect the server cold plate integrity and performance. Most systems feature integrated leak detection, intelligent flow monitoring devices, and alarm features to maintain system performance and protect data center equipment.

The Vertiv™ Liebert® XDU 070 cooling distribution unit functions as a liquid-to-air heat exchanger for cooling chips.

Liquid-to-liquid CDUs

Liquid-to-liquid CDUs yield the best cooling performance. However, they require installing pipes and pumps to connect to the facility's water.

Liquid-to-air CDUs

Though limited in cooling capacity and capability compared to other devices, the products in this category do not require water pipes to be connected to the building system for heat rejection. Liquid-to-air CDUs can be installed more efficiently, take less space, and have lower installation and initial costs than liquid-to-liquid CDUs. They enable localized liquid cooling for high-output IT equipment but leverage the technologies from existing data center cooling systems to dissipate heat.

Benefits of a Coolant Distribution Unit

Efficient Cooling

CDUs are more compact and flexible than traditional air conditioning systems. Because of their smaller size and weight, they can also be located closer to the cooled server, which requires less energy because they don't need to distribute coolant over an entire room or building.

CDUs can achieve significant energy savings compared to traditional air conditioners or chillers by reducing power consumption while increasing system uptime and reliability – leading to lower operating costs in the long run.

Precise Temperature Control

CDUs can also help protect data centers from potential damage due to overheating. Due to specialized controllers, CDUs can maintain precise temperatures from -20°C (-4˚F) up to a maximum of +70°C (158˚F), making it easier for data center operators to customize their requirements. This prevents component failure or even fire hazards.

Redundancy

Redundant pumps and power inputs ensure continuous operation and that precise temperature, flow rate, and pressure are continuously maintained, thus ensuring uptime and increasing reliability.

Conclusion

Coolant Distribution Units (CDUs) are essential in data centers with high-density applications providing close controlled coolant delivery and precise control of the liquid cooling system. They help manage heat loads, reduce power consumption, and increase efficiency and reliability through redundancy. CDUs also promote environmental sustainability by decreasing carbon dioxide emissions.

The Vertiv™ Liebert® XDU Coolant Distribution Unit Family